Understanding Air Chutes in Refrigerated Trailer Operations

By Tim Ifland, VP of Specialty Equipment

Air circulation is one of the most crucial factors in protecting refrigerated loads of perishable or otherwise temperature-sensitive goods. But temperature control capabilities are meaningless if the appropriately cooled or heated air is not circulated properly throughout the trailer unit.

And that’s where air chutes come in. Air chutes can play a significant role in keeping the climate within the trailer cargo space at optimal conditions because they distribute air evenly and consistently throughout the trailer to help reduce the risk of a load loss. But are they right for your reefer operation? That’s what we want to dive into in this article.

So, what do air chutes really do?

Air chutes were designed to direct the air within a reefer in an ideal flow to achieve consistent temperature throughout. They are attached to the roof of the trailer, receive the air from the refrigeration unit and deploy it through the sides and back.

To understand the directions of the circulation, imagine you stand on the left side of a trailer. From here the air flows in clockwise from the front to the back or your trailer, as well as from top to bottom throughout.

Thermo King: Air Chute - How does it work? - YouTube

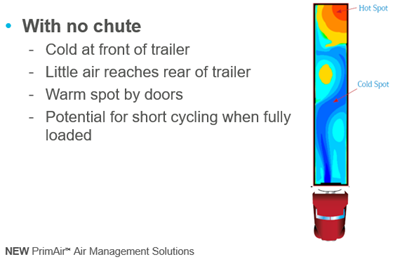

Source: PrimAir Management System | Parts & Accessories | Thermo King

In addition to the distribution of the cold/warm air coming from the reefer unit, air circulation also carries product temperature and thermal transfer of cold/warm air that penetrates through the walls, floors, and ceiling of the trailer, back to the refrigeration unit where it can be adjusted.

“Having chutes distribute air evenly reduces the likelihood of temperature gaps or ‘hot spots’ within various parts of the trailer. A typical hot spot you may find is right by the left reefer door, which is often where temperatures are measured.” – Joe Bromley, VP – Strategic Sourcing, Premier Trailer Leasing

Let’s investigate the design of reefer trailer air chutes more deeply...

Air Chute Design

While the original design of truck trailer air chutes was static and prone to tears due to the end of the air chute hanging down into the cargo area, the newest air chutes are made of flexible material that allows them to automatically expand and contract (inflate or deflate) when the reefer unit is turned on and off. When the reefer is not in use, they stay out of the way for limited risk or damage. When the reefer is turned on, the air chute inflates and does its job.

Another feature you will come across when reviewing air chute designs is a ramped mesh material at the end of the chute that allows it to be fastened to the roof and still get good airflow performance to the rear of the trailer. It helps reduce the risk of snags from a forklift and/or freight during the loading and unloading process.

So, should you add air-chutes to your reefers and what to keep in mind?

Some truck fleet operators welcome air chutes, while others are not so keen on their use. They have been an obstruction to loading and unloading and tended to get in the way. In the past, some of them were made of a hard plastic material. When loading and unloading trailers, they would get bumped, causing the roof fasteners to break loose and then become easily snagged and be torn down. Because of this they were sometimes not used.

Some shippers are known to stuff as much freight into the interior with no concern about proper airflow, putting the carrier at risk of maintaining proper temperature compliance which could result in a rejected load, a claim loss and a tarnished record with their customer.

On the flipside, trailers without air chutes can be prone to problems. Product at the front of the trailer is subject to top freeze. Insufficient volume of air reaching the back of the trailer can result in cold spots in the trailer front and warm spots in the back. As the warmer air returns to the unit, the unit blows air colder than the desired setpoint into the trailer. Such a condition can in turn lead to short cycling of the refrigeration unit.

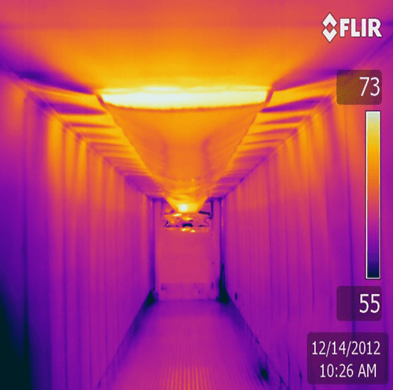

When a reefer unit has a smooth, uniform flow of air, it operates efficiently which can improve air flow by nearly 20%, which equates to better fuel performance, less maintenance problems, a longer lifespan, less repair costs and a reduced risk of losing a load. Notice the infrared airflow distribution out the sides and rear of the chute for optimal airflow distribution.

Source: PrimAir™ Mangement System (thermoking.com)

The takeaway? Circulating air with chutes doesn’t just benefit the load, it also supports the lifecycle of the reefer unit and helps it operate more efficiently.

Luckily air chute designs have been optimized in a way that makes them much more robust and user friendly which is why we here at Premier have come to offer them on all our refrigerated trailers.

If you do decide to leverage air chutes in your reefer operation, there a few things you should keep in mind:

- Rips and tears in a chute are still common so teams should be trained to examine their air chutes on a regular basis to ensure they are intact.

- Chutes can be fixed fairly easily. Sign up for our post updates and stay tuned for more on this topic soon!

- Chutes also need to be kept clean and free of any dirt and/or debris.

Load Management and Air Chutes

While air chutes reduce the negative impact of disadvantageous load organization on the cargo, the right load organization within the trailer is still essential.

- To prevent the blocking of air circulation between the load and the rear doors in the event of load shift, vertical channels or ribs can be placed on the inside of the rear doors. Another option are cross bracings at the rear of the load.

- High airflow floors allow air to circulate under the load. About 240 square inches of return air passage are needed for the average trailer’s refrigeration fan to operate at 100 percent capacity. The product should be loaded on pallets or floor racks when space for air circulation under the load is inadequate due to floor design.

- All air that is pushed into the reefer also has to come back. If the return air is blocked however, the fan will turn, but no longer blow air. That is why a strategic front bulkhead design is critical for ideal air free return to the refrigeration unit.

- The bulkhead should be positioned a minimum of 3 inches from the front wall.

- A minimum of 6 inches of open space should be left between the bottom of the floor and the bottom edge of the bulkhead.

- The top side of the bulkhead should have 30 to 50 square inches of open area to allow mixing of top and bottom air, and to allow some return air to the thermostat should the airflow be interrupted by improper loading or load shift.

- Bumpers or vertical strips should be attached to the area at the bottom of the bulkhead wall to prevent the load from blocking air return to the blower under the bulkhead.

- Most modern air chutes also utilize return air bulkheads. These bulkheads some with side air discharges to direct at least a portion of the airflow along the length of the chute.

Air Chutes in the wild. A real world story.

I want to close this post with a real-world story. A few years ago, I was working with a customer who had previously not been sold on reefer air chutes. He had decided to go without them as he was in the full swing of Valentine’s Day preparations, loading his reefers with roses and other flowers.

As often the case during this season, he leveraged reefers as warehouse space for the fragile cargo, when he realized the way his team had loaded the trailers was not ideal. Within just a few hours, the southern heat destroyed multiple loads of expensive flowers and damaged his relationship to the retail customer. When he told me this story he was adamant to only lease reefers with air chutes from that day forward.

In Summary…

With an average value of approx. $60k in value, nobody wants to risk losing a cargo load because of inadequate air flow and elevated temperatures. Air chutes play a key role in truck trailers and truck transport when perishable or temperature-sensitive cargo is involved. Knowing the purpose of air chutes as well as their design and construction, helps shippers and carriers make the best decisions regarding their use in modern supply chain operations.

Thanks to the many different designs developed over the years, air chutes today offer an effective solution to air flow management that ensures reefers can do a consistently reliable job.

Contact us for more information - Premier offers 36 locations and more than 50,000 trailers to meet your fleet leasing needs. We'd love to be a resource for you and your team as well!

Tim Ifland is Vice President Specialty Equipment for Premier Trailer Leasing and an industry veteran. His 35 years of trailer industry experience includes branch operations, sales management, procurement, product SME/sales training, account management and branch equipment services including warranty, quality control, breakdown services, tires, maintenance and safety.

Tim Ifland is Vice President Specialty Equipment for Premier Trailer Leasing and an industry veteran. His 35 years of trailer industry experience includes branch operations, sales management, procurement, product SME/sales training, account management and branch equipment services including warranty, quality control, breakdown services, tires, maintenance and safety.