Plain Talk About A Debate As Old As Trucks and Trailers

by Ryan Moenke

Payload protection, extended trailer component life, maintenance cost reduction, driver satisfaction… Cushioning the ride through shock absorption plays several key roles in fleet management. However, deciding which suspension type is best for your fleet can be tricky.

When a suspension works well, it stabilizes the trailer and allows the tires to firmly grip the road which results in better driver control and hence, a safer operation. There are two key options available today: air ride and spring ride suspensions.

In my experience, most of the published studies available to the industry are biased opinions. Let's walk through the basics to help you decode the best option for your fleet.

The ABCs of Air and Spring Ride Suspensions

Spring Ride Suspensions

On a basic level, trailer spring suspensions use a stack of two or three semi-elliptical steel strips (“leaves”) of different lengths, bound together and shaped like an archer’s bow. The ends of the bow are connected to mounting brackets (“hangers”) either directly attached to the trailer subframe or to the side rails of the sliding bogie. The trailer axle is U-bolted beneath the low point of the spring pack curve so when the trailer body moves up or down, the spring pack flexes to absorb the shock and cushion the ride.

In some newer models of spring suspensions, the leaves are made from “composite” materials. Depending on the operational application and design, these springs may vary in the number of leaves and/or may have additional traditional shock absorber support. The basic claimed advantages of composite versus steel are the lighter weight of composite material, improved cushioning, and extended useful life. Standard steel spring ride suspensions are 50 – 75 pounds lighter than most air suspensions.

Air Ride Suspensions

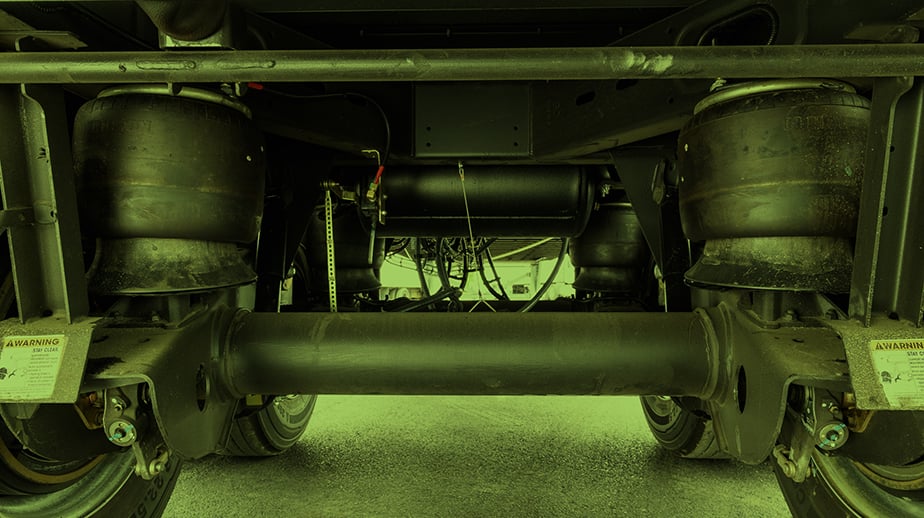

Trailer air ride suspensions on the other hand use pressurized, expandable rubber or rubber-like bags instead of the steel/composite spring packs to absorb the road shocks and changing weights of the trailer loads.

The bags are located between the axles and the trailer sub-structure and air pressure is supplied to the bags by the same air compressor and reservoir as the truck’s braking system. A network of air lines and valves maintains the right pressure in the bags. When working properly, an air suspension automatically adapts to changing cargo loads and road shocks keeping the floor mostly level and providing a constant, smooth ride. Air suspensions are also known to produce less vibration than spring suspensions resulting in reduced maintenance expense throughout the rest of the trailer.

Which Suspension is Right For You? Selecting the Ideal Suspension: Factors Influencing Your Decision

Despite some claims to the contrary, there is currently no testing data from available studies that show clear differences in tire wear or safety between air and spring rides. So how do you make the right decision for your fleet? We recommend you consider a few variables affecting ride quality, performance, cost, and how the two suspension types compare.

#1: Payload Weight

Trailers behave very differently based on the weight they carry. Empty trailers bounce around more…partially loaded trailers less so…and fully loaded trailers bounce the least (gripping the road the best) for a smoother ride. Spring ride trailers perform best when the payload is between 30-45k lbs. Air ride adjusts based on the weight of the trailer to provide the correct amount of pressure in the air springs.

#2: Cargo Distribution

Similar to load weight, distribution of the load in the trailer has a measurable effect on suspension effectiveness.

- If the cargo is exclusively loaded in the nose, it mostly sits over the tractor’s drive axle suspension while the empty trailer rear over the suspension tends to bounce and flop causing less continuous connection to the pavement.

- If the cargo is evenly distributed or loaded mid-ship between the landing gear and slide track the trailer suspension will perform more smoothly.

- If the cargo is loaded heavily in the rear of the trailer, there have been reports that the trailer nose can potentially lift the 5th wheel of the tractor to be an inch or more over height. There have also been some reports that trailers heavily loaded in the rear may be more prone to jack-knifing in adverse road conditions.

#3: Road Conditions and Speed

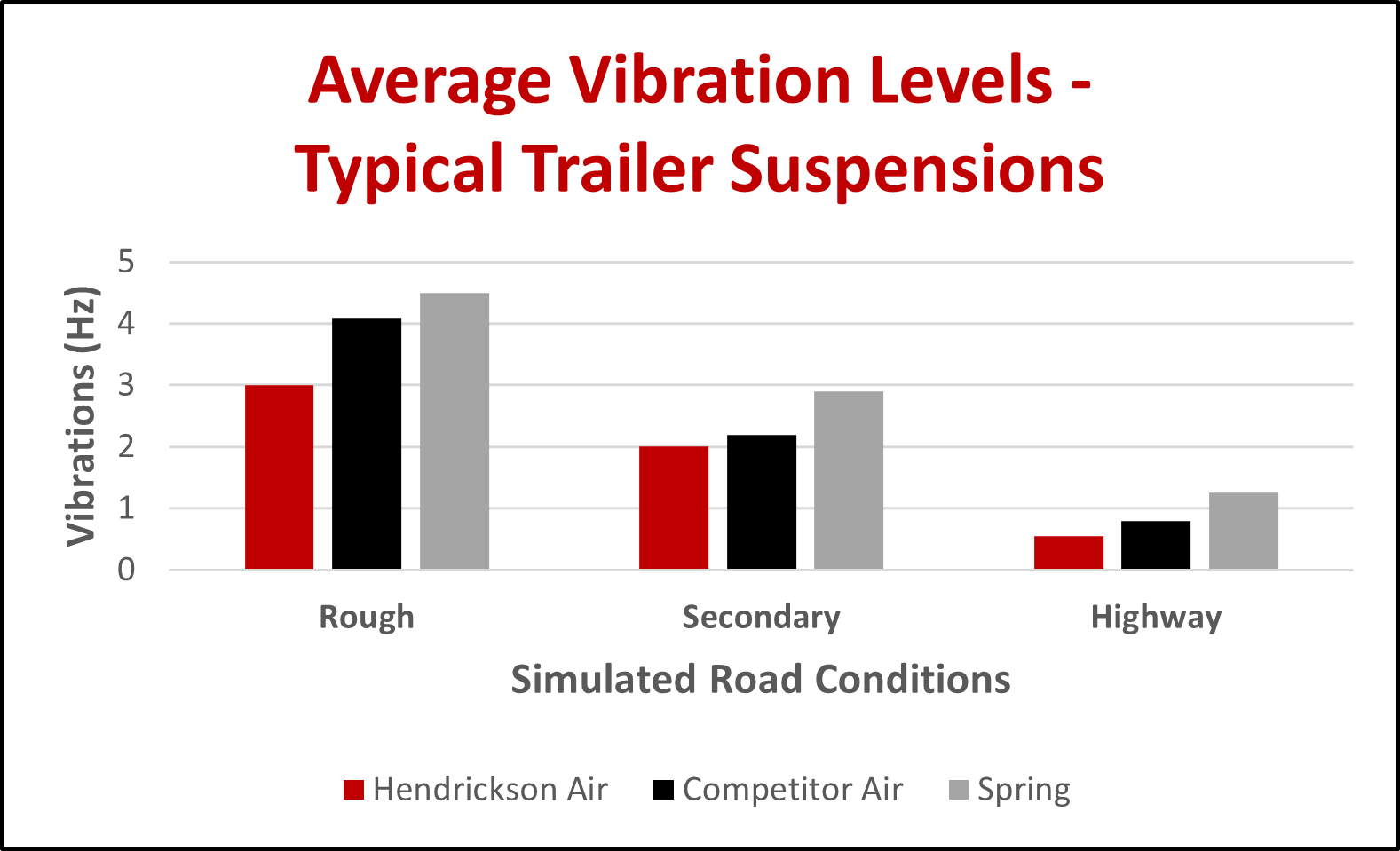

Rough roads, especially at higher speeds will hamper any suspension’s shock absorption performance and resulting ride quality ride as shown in the chart below from air ride provider Hendrickson.

Source: Hendrickson Commercial Vehicle Systems, 2019

The above data is based on internal testing and/or published studies and specifications.

Actual product specifications and performance may vary depending upon the suspension

And vehicle configuration, operation, service, and other factors.

#4: Safety

Both air and spring ride suspensions are equally safe assuming regular inspections and proper maintenance and operation. A broad review of available studies and test data shows no evidence that either suspension offers superior safety benefits.

#5: Performance & Operational Characteristics

Examining ride height consistency, dock hopping solutions, and the influence of sensitive cargo on your suspension choice, are all crucial factors that impact the operational characteristics of your fleet.

- Ride Height – Continuous pressurization of the airbags keeps the ride height of an air ride trailer constant under changing payloads as long as the trailer is connected to the tractor air supply. By comparison, spring ride trailers will “slump” under very heavy loads.

- Dock Hop – Trailers are prone to bounce while loaded forklift trucks move in and out from the loading dock. Air ride suspensions can tend to “walk” away from the dock. This can be largely controlled with the addition of mechanical devices on the suspension, which typically comes as standard equipment on modern suspensions and/or the use of dock locks. The air system used in air ride trailers can also be used to raise and lower the dock height of the trailer floor in some situations which may make loading and unloading easier.

- Sensitive Cargo – While many of the points in this article are optional considerations, this one may be the deciding factor for you: Many shippers require air ride trailers for their cargo. Keeping this in mind, using air ride trailers allows you to be flexible no matter who you are hauling for.

- Maintenance – Inspection of spring ride suspensions is recommended every 12 months or 25,000 miles. The inspection is mainly a visual checklist, but the torque of the U-bolts and other fasteners should be checked and adjusted as needed. Air ride suspensions require routine inspections as well. Fleets may start to see airbag failures after 7-8 years depending on application, which can increase maintenance expense. Aside from airbag replacements, the two suspensions see similar lifecycle costs.

- Driver Satisfaction – Most truck drivers today prefer to pull air ride trailers versus spring rides. This is especially true when deadheading empty trailers or hauling lighter payloads due to the bouncier ride of a spring ride trailer. With driver satisfaction and retention a major industry challenge, many fleet owners are influenced favorably toward air rides to keep drivers happy.

#6: Cost Analysis

Traditional price gaps between air and spring ride trailers have narrowed over time due to air ride’s popularity since the ‘90s. Today, the trailer cost difference varies between a $500 -$1,000 premium for new air ride trailers depending on the quantity purchased and optional features included. However, carriers and shippers may still find increased value in operating air instead of spring. Driver preference and shipper requirements alone may outweigh the dollars and cents premium but adding the flexibility to be able to pull any load.

Decoding Technical Jargon for Practical Insight

In the realm of trailer suspensions, technical terminology often dominates discussions, potentially overwhelming non-engineering readers. To facilitate understanding, let's simplify some key terms:

- Damping: Refers to shock absorption

- Natural Vibration Frequency: The rate at which an object vibrates naturally when disturbed (eg a trailer suspension going over a bump) and generally measured in units called Hertz or Hz for short

- Power Spectral Density (PSD): Describes the amplitude and frequency (eg, vibration) of the wave action of the suspension as measured by instruments called accelerometers and depicted on an X Y axis graph. The higher the amplitude (Y or vertical axis) of a suspension the bigger (and less controlled) the bounce as compared to the vibration frequency (X or horizontal axis)

- Vertical Acceleration: The velocity at which the suspension moves up and down relative to gravitational forces and measured in g’s

- Hysteresis: Loss of mechanical energy (eg, bounce or spring characteristics) from static friction (eg, striction) between the spring leaves

Making Your Decision: Navigating Your Fleet's Unique Needs

So, after all this information, are air or spring rides better for your fleet? It depends! Operating requirements of every fleet differ based on freight, service area, maintenance capabilities, cost sensitivity, etc. so it is up to you to weigh the pros and cons we shared against your unique applications.

With over 50,000 trailers that carry a wide variety of cargo, we here at Premier have decided to equip most of our trailers with air-ride suspension. This not only offers the most load flexibility for our customers, it also helps them support their drivers.

We hope this article can help you in deciding the right equipment type for your needs. If you have questions or need help in your decision, please reach out to us. We’re always here to help.

Ryan is a Regional Sales Director at Premier Trailer Leasing. With over a decade in the industry, Ryan is a seasoned trailer expert, striving to support his clients with the best trailer fleet recommendations to meet their unique needs. Connect with Ryan on LinkedIn to pick his brain. ![]()

Want to learn even more? Check out the history of trailer suspensions!

We could begin as long ago as 1901 with the first versions of air ride suspensions versus traditional steel springs on horse-drawn wagons, but that would probably be TMI. Instead, let’s start with the modern-day trucking industry born after World War II.

Trucking after the war was booming. Freight that was traditionally moved by rail started to be delivered door to door faster and more competitively by truck. Beginning in the mid ‘50’s, Eisenhower’s interstate highway system catapulted increasing demand for trucking into the next decade and the industry’s growth hasn’t looked back since. Today, virtually everything we buy, eat, wear, work, or play with comes to us at least part of the way by truck.

That said, truck and trailer design specifications have evolved considerably in that same 75 years. In the ‘40s, ‘50s, and ‘60s there was a hodge-podge of trailer sizes and specs due to a mix of state regulations and the fast pace of engineering innovations. For the most part, however, spring ride trailer suspensions dominated while air ride applications were used only in rare, specialty situations. Typical trailer sizes were 36’, 40’, 42’, or 45’ long with fixed suspensions and single or two-leaf steel springs. Longer than those used today, steel springs provided excellent road shock absorption and vehicle stability for its day. By comparison, air ride suspensions were expensive, more prone to failure, and a larger maintenance expense. The perceived difference in ride quality between air and spring was minuscule and the reliability of “tried and true” spring suspension ruled the day.

As they say, the only constant is change, so in the 1970s trailer sizes moved to 45’ and then (courtesy of the 1982 Surface Transportation Assistance Act – STAA) to 48’. Increasing the length of the trailer forced the development of the sliding tandem to provide more flexible operation and maneuverability on differing roads, and pick-up/delivery locations. This created the need to shorten spring lengths to fit the sliding tandem geometry while minimizing weight and cost. Even by increasing the number of leaves to two or three layers per spring, the ride quality suffered (less shock absorption, harder ride), particularly when the trailer ran empty.

By the late ‘80s and early ‘90s, the industry was rapidly moving to a new standard of 53’ trailers and the gap in ride quality between spring and air had narrowed. Although air ride design and performance had improved, the purchase price was still a $1,500 premium per trailer (on a $12,000 - $15,000 dry van). Spring ride was less expensive but large trailer fleet owners were more focused on growing their market share by offering a “premium” product.

The resulting popularity shift in the spring versus air debate was nothing less than remarkable through the 1990s and 2000s resulting in air ride dominating the dry freight trailer, reefer, and flatbed markets with an estimated 70% + share. The scale of air ride’s popularity helped to reduce the initial cost gap with spring rides and allowed air ride providers to make further improvements in the product.

During the same 20 years, spring ride trailer products improved technologically in both design and resulting ride quality while remaining considerably less expensive on a full life cycle basis. Despite the lower cost, only the rail/marine intermodal and LTL trucking markets remained steadfastly locked into spring ride trailer suspensions.

Today, air ride trailer suspensions continue to be the popular standard in the dry van, reefer, and flatbed industry segments.

.jpg?width=960&length=960&name=924x518_MM_air-ride_spring-ride%20(1).jpg)